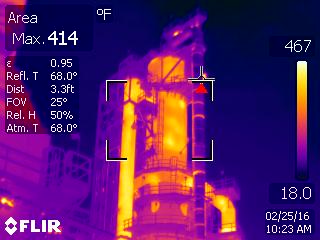

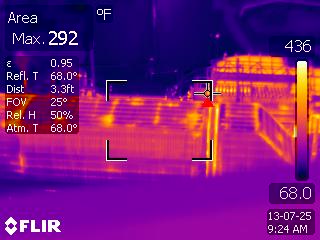

Infrared (IR) thermography technology is widely used in the oil and gas industry as an inspection tool for condition monitoring and predictive maintenance. It is advantageous over traditional visual inspection and other tools because infrared technology does not have to be in contact with the equipment being monitored.

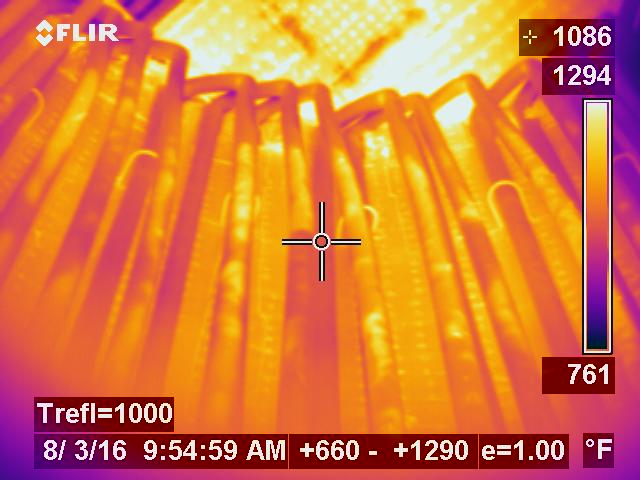

IR thermography is a form of nondestructive testing that measures temperature variances of a component as heat (i.e. thermal radiation) flows through, from, or to that component.

The purpose of mapping temperature levels and variances of a component is to detect any hot spots where equipment may weaken or fail. IR thermography is also capable of detecting corrosion damage, delaminations, voids, inclusions, and other flaws that affect heat transfer. However, in order to detect these anomalies, there must be sufficient temperature difference between the component and its surroundings.