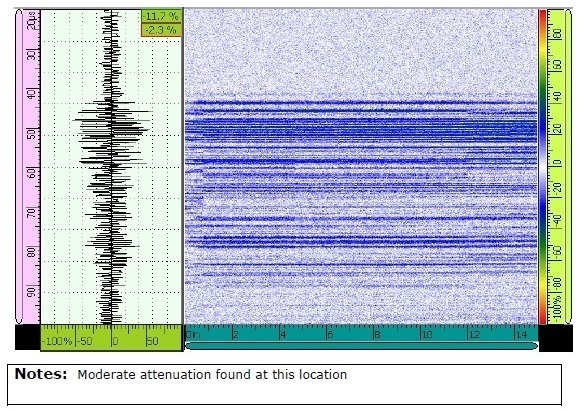

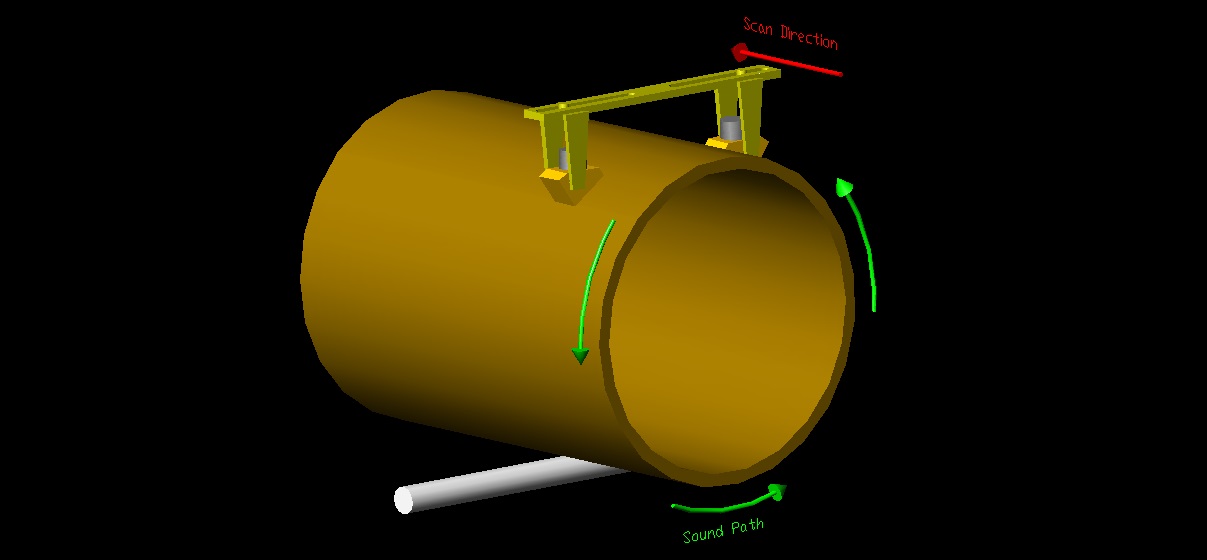

Contact Point Inspection is an advanced NDE method that uses the CHIME technique for the rapid screening for, and flagging of, defects in inaccessible areas. CHIME is the transmission of ultrasound between two probes placed a distance apart in parallel (or near parallel) walled material. The sound travels as a Creeping wave along the surfaces and as a Head wave between the surfaces. The unique way in which the waves propagate provides complete isonification of plate or pipe with little attenuation allowing the transmitting and receiving probes to be well separated. CHIME acts as an ideal technique to carry out initial screening to locate regions of corrosion and then to examine the flagged areas in more detail with thickness monitoring.

Some applications that have been identified are: Inaccessible regions such as pipe supports, saddles, riser clamps, tank floors and pipes with limited access, e.g. half buried.